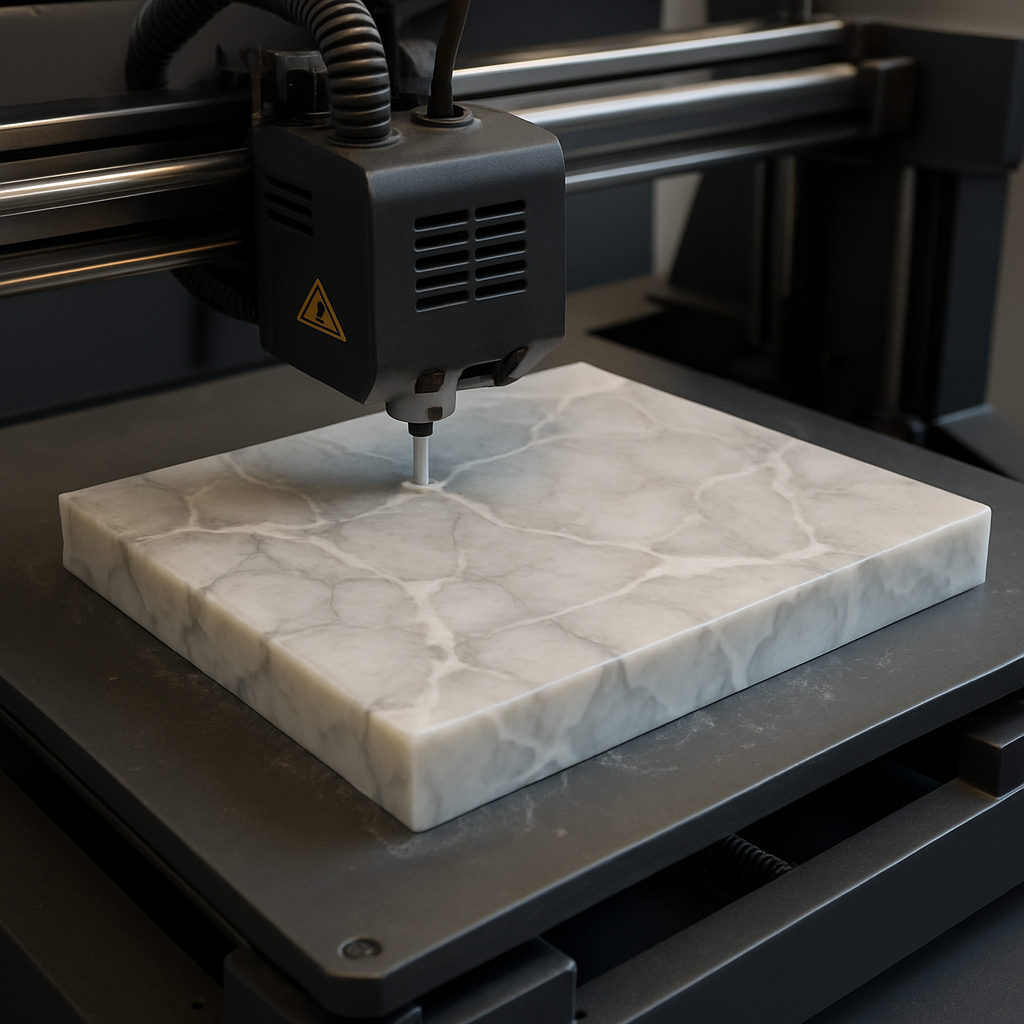

3D Printed Quartz Slab

In recent years, the advent of 3D printing technology has revolutionized many industries. One exciting development in this field is the creation of 3D printed quartz slabs. This innovative process is transforming quartz fabrication, providing new possibilities for design and construction. In this article, we’ll explore what 3D printed quartz slabs are, how they are made, and the benefits they offer.

A 3D printed quartz slab is a man-made product created using advanced 3D printing techniques. Unlike traditional quartz slabs, which are cut from large blocks of quartz stone, 3D printed slabs are fabricated layer by layer. This process allows for more intricate designs and customized shapes that were previously impossible to achieve.

The Process of Quartz 3D Printing

The process of quartz 3D printing involves several steps:

- Design: The first step is creating a digital model of the slab using computer-aided design (CAD) software. This model serves as the blueprint for the 3D printer.

- Material Preparation: Quartz powder is mixed with a binding agent to create a printable material. This mixture is loaded into the 3D printer.

- Printing: The 3D printer follows the digital model to deposit the quartz mixture layer by layer. Each layer is carefully cured with UV light or heat to solidify it before the next layer is added.

- Finishing: Once the printing is complete, the slab undergoes finishing processes such as polishing and sealing to enhance its appearance and durability.

The Role of Technology in Quartz Fabrication

The integration of technology in quartz fabrication has opened up new possibilities for creativity and efficiency. With 3D printing, designers can experiment with complex geometries and intricate patterns that were not feasible with traditional methods. This technology also reduces waste by using only the necessary amount of material for each slab.

Benefits of 3D Printed Quartz Slabs

3D printed quartz slabs offer several advantages over traditional quartz slabs:

Customization and Design Flexibility

With 3D printing, there are virtually no limits to the shapes and patterns that can be created. This allows architects and designers to push the boundaries of creativity and produce unique pieces tailored to specific projects.

Sustainability

The precision of 3D printing minimizes material waste, making it a more sustainable option compared to conventional fabrication methods. Additionally, the ability to produce slabs locally reduces the carbon footprint associated with transportation.

Cost Efficiency

While the initial investment in 3D printing technology can be high, the long-term cost savings are significant. The reduction in waste and the ability to produce on-demand slabs can lead to lower production costs.

Enhanced Durability

3D printed quartz slabs are known for their strength and durability. The layer-by-layer construction process ensures a consistent and dense composition, resulting in a robust final product.

Applications of 3D Printed Quartz Slabs

The versatility of 3D printed quartz slabs makes them suitable for a wide range of applications:

Interior Design

In interior design, 3D printed quartz slabs are used for countertops, flooring, and wall panels. Their customizable nature allows designers to create bespoke interiors that stand out.

Architecture

Architects are increasingly incorporating 3D printed quartz slabs in their projects. From facades to structural elements, the material offers both aesthetic appeal and structural integrity.

Art and Sculpture

Artists are also embracing this technology to create stunning sculptures and installations. The ability to print intricate designs enables artists to explore new creative avenues.

The Future of Quartz 3D Printing

As technology continues to evolve, the potential for 3D printed quartz slabs is immense. Researchers are exploring new materials and methods to further enhance the properties of these slabs. We can expect to see even more innovative applications and designs in the coming years.

Challenges and Considerations

Despite the many benefits, there are some challenges associated with quartz 3D printing. These include the high cost of equipment and the need for skilled operators to manage the printing process. Additionally, ensuring the quality and consistency of the printed slabs can be a complex task.

Conclusion

3D printed quartz slabs represent a significant advancement in quartz fabrication. With their limitless design possibilities, sustainable nature, and cost efficiency, they are poised to become a staple in modern construction and design. As technology progresses, we can look forward to even more exciting developments in the field of quartz 3D printing.

The future of 3D printed quartz slabs is bright, and their impact on the industry is only just beginning. Whether you’re an architect, designer, or artist, this technology offers a world of possibilities waiting to be explored.

Post time: Sep-01-2025